Construction

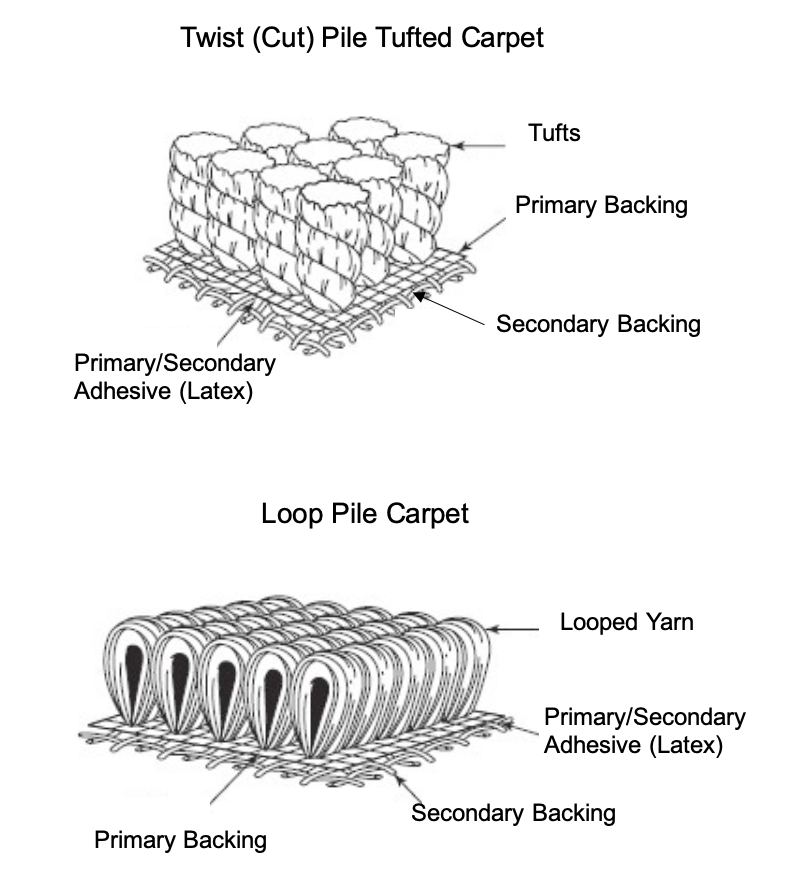

The loops of yarn are either left in place for loop-style carpets, such as Berbers, or cut with blades for cut-pile carpet. There are a variety of different finishes in carpets; Loop pile carpets can be a single level or multilevel loop, there can even be a mix of loop and cut piles, along with multilevel loops giving many different pattern variations and finishes. Tufted carpets can be: standard twist, Saxony, frieze, Chunky, velvet plush, in single, two, three and four ply yarns adding to the finishes available.

Carpet Fibres & Yarns

All carpets are made from either natural fibres, man made fibres or a combination of both that are spun into yarn that is then woven or tufted into the finished article to be found in carpet retailers throughout the globe.

Raw fibres are blended together in precise proportions according to the �character� and �handle� of the yarn required for the carpet in question.

The blend is scoured, pulled and teased until it is straighter, whiter and free of natural burs and foreign bodies. The fibre is systematically opened up, layered and cross layered before the resulting �web� or �spat� is split into �slubbings� that are then pulled and twisted on a spinning frame. This helps to add strength to the single strand of yarn. Two or more of these strands are then twisted together � �doubled� � and this results in a yarn with high tensile strength capable of being tufted or woven by the latest high-speed machinery at maximum efficiency and at the lowest production cost.

Colour is introduced either at the raw fibre stage or when the yarn is spun into the thickness and length suitable for the carpet in question.

If the fibre is solution-dyed, a technology that is only available in man made fibres, the colour is added at the polymer stage. This ensures that whatever shade chosen is actually an inherent part of the fibre which gives solution-dyed carpets extra durability. These fibres are particularly resistant to prolonged exposure to UV-light and will not be face adverse fading should they be exposed to harsh cleaning chemicals.

Other than the material, the durability of a carpet depends on several factors: density of the tufts, twists of the yarn, and heat setting.

Carpet Density

Density refers to how much yarn is used in the pile. The more tufts of yarn per square inch, the more yarn there is to wear and provide a resilient surface that resists crushing. The denser a carpet, the harder it is to push through the carpet to the backing with your fingers.

Also, when bent back in a U-shape with the pile facing outward, a denser carpet will show less of the backing. Density is measured in stitches per inch or face weight, which is the weight of the fiber in the pile per square yard of carpet.

Yarn Twist

Twisting the yarn enhances the durability, particularly in cut-pile carpets. In most nylon, polypropylene, and polyester cut piles, the twist is set by heat or steam to help the carpet retain the twist. The cut ends of the carpet pile should be neat and tight. Higher piles create a softer feel and more luxurious appearance but tend to crush more easily and are more difficult to clean.

Most carpeting today is very colourfast. Solution-dyed carpet, in which the dye is added to the fibers when they are made, is extremely colourfast. Yarn dyed carpet, which is dyed after the yarn is made, provides some colour variation and is also very colourfast. In general, light-coloured carpets show dirt and stains, while dark colors show lint. Mottled colours such as tweeds and textured patterns tend to disguise dirt and wear, and are good choices for high-traffic areas and rooms where spills or stains are likely

Natural Fibres

Wool

The most popular of natural fibres, wool is exceptionally suited to being used as a carpet fibre because it combines excellent resistance to foot fall with an uncanny knack of looking good for years. Wool Carpets are also resistant to combustion and under normal conditions provide a great anti-static flooring option.

Wool carpets tend to be made from either or from New Zealand Wool and each have their own distinct properties. British wools are notoriously tough and hard to beat when wear is a main concern. Whereas, New Zealand wool is better for dyeing lighter shades.

Silk

Being so delicate, silk is rarely used in carpet but it does bring a certain something to the finest hand made rugs, particularly those from the Middle East and Indian regions.

Jute

Used mainly in the backing of carpets from a traditional point of view, jute is gaining popularity as a natural fibre floorcovering and its depth of texture makes it great for rugs.

Coir

Coir is made from the fibres of coconut husks and it is a strong and resilient fibre. The pale yellow fibres are spun into yarn that is woven into flat weave carpeting or as many people will recognise it, into cut pile doormats that are great at removing dirt and moisture from soles.

Flax

Only used occasionally in loop pile and flat weave rugs and carpets.

Sisal

These are some of the toughest fibres in the business and unlike most natural fibres it can be dyed. When combined with wool, sisal can also take on a softer side and is being favoured by natural flooring manufacturers for its aptitude at creating colourful, natural floors.

Seagrass

Coming from the paddy fields of China, Seagrass is a rapidly replenishing resource. Once the fields have been flooded with seawater, the fibre is harvested and spun into yarn that has an impermeable quality. While this makes it hard to dye, it also makes it relatively easy to care for.

Man Made Fibres

These products have specific performance properties that marry well with the fibres� tenacity for design flexibility. Solution-dyed man made fibres are now an increasingly important part of many manufacturers� ranges.

Acrylic

Not as hard wearing as nylon and less fire resistant than wool, acrylic can still bring bulk and pile resilience to a carpet.

Polyamide (Nylon)

Nylon carpet fibres take two forms, Nylon Type 6 and Nylon Type 6.6. Type 6 is often added to wool to create a woolrich carpet with increased wear resistance, particularly in lower pile weights and densities.

Nylon Type 6.6 has some extra bells and whistles in its molecular structure providing an extremely hard wearing fibre that by many is now considered the industry standard within commercial contract locations.

Polyester

Polyester carpet fibre gives a luxurious feel to thick, cut pile styles and it also provides a good depth of colour. However, it is not as resistant to flattening as some other fibres although it does wear well and provides good resistance to water-soluble stains.

See a selection of Polyester carpet

Polypropylene

Polypropylene is widely used in carpet manufacturing, either as part of a blend, or in its own right. It withstands footfall well, Polypropylene has an inherently high tensile strength and an unrivalled ability to withstand the wear and tear, the fibres are resilient and have an inbuilt ability to deflect dust & dirt, spills & stains of even the busiest households.

Viscose

A relatively inexpensive fibre, viscose is not particularly resilient and it has a habit of flattening fairly easily. However, it does allow fitted carpets to be brought within easy reach.